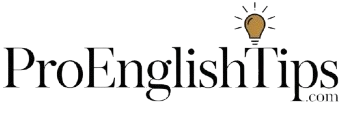

In the realm of craftsmanship and construction, two similarly spelled words often cause confusion: lathe and lath. While they might sound alike, these terms represent entirely different tools and materials, each serving unique purposes in woodworking and building construction.

The Mighty Lathe Machine

A lathe machine stands as a cornerstone of material shaping technology. This sophisticated machine tool transforms raw materials into precisely crafted cylindrical objects through rotational motion. Whether you’re working with a wood lathe for creative projects or a metal lathe for industrial applications, the principles remain consistent.

| Lathe Type | Primary Materials | Common Applications |

|---|---|---|

| Mini Lathe | Wood, Soft Metals | Pen Making, Small Parts |

| Benchtop Lathe | Hardwood, Brass | Table Legs, Bowls |

| Industrial Lathe | Steel, Aluminum | Machine Parts |

| CNC Lathe | Various Metals | Precision Components |

| Wood Turning Lathe | Hardwood, Softwood | Furniture Parts |

| Engine Lathe | Steel, Iron | Industrial Components |

| Tool Room Lathe | Various Metals | Custom Tools |

| Speed Lathe | Wood, Plastics | Quick Turning Projects |

| Heavy Duty Lathe | Large Metal Stock | Industrial Parts |

| Combination Lathe | Multiple Materials | Versatile Projects |

John Davidson, a master craftsman from Portland, recently emailed his apprentice about a woodworking equipment purchase: “The new wood lathe arrived today. Its precision in wood turning is remarkable. Perfect for those custom table leg orders we’ve been getting.”

You Might Like: Pre vs Post: Which Prefix to Use?

Traditional Lath Applications

In contrast, construction lath plays a vital role in building material applications. These thin, closely spaced strips create a foundation for various construction projects. Wooden lath and plaster lath have been fundamental elements in traditional construction methods.

| Lath Material | Durability Rating | Best Applications |

|---|---|---|

| Metal Lath | 25+ years | Stucco Exterior |

| Wood Lath | 15-20 years | Interior Plaster |

| Plastic Lath | 30+ years | Modern Construction |

| Diamond Lath | 25+ years | Curved Surfaces |

| Bamboo Lath | 10-15 years | Eco-Friendly Builds |

| Expanded Lath | 20+ years | Heavy Plaster |

| Wire Lath | 25+ years | Concrete Support |

| Ceramic Lath | 30+ years | High-Temp Areas |

| Composite Lath | 25+ years | Moisture-Prone Zones |

| Fiber Lath | 20+ years | Light Applications |

Practical Applications in Modern Construction

The implementation of lath strips in wall framework continues to evolve. Sarah Martinez, a construction supervisor, detailed in her site report: “We’re incorporating modern metal lath for the stucco installation, ensuring better adherence and longevity compared to traditional methods.”

| Construction Method | Installation Time | Labor Cost |

|---|---|---|

| Traditional Plastering | 5-7 days | High |

| Modern Lath Systems | 3-4 days | Medium |

| Hybrid Techniques | 4-6 days | Medium-High |

| Direct Application | 2-3 days | Low |

| Mechanical Fastening | 3-5 days | Medium |

| Wire Mesh System | 4-5 days | Medium-High |

| Expanded Metal | 3-4 days | Medium |

| Paper-Backed Lath | 4-5 days | Medium |

| Self-Furring | 3-4 days | Medium-Low |

| Double Layer | 6-8 days | Very High |

The Art of Woodworking

When discussing woodworking tools, the distinction between lathe and lath becomes crucial. A woodworker’s email to a supplier might read: “I need a robust metalworking tool for my expanding workshop. The current wood lathe handles the woodworking projects well, but I’m looking to diversify into metal crafting.”

| Tool Category | Maintenance Frequency | Skill Level Required |

|---|---|---|

| Basic Lathe | Monthly | Beginner |

| Professional Lathe | Weekly | Advanced |

| Industrial Lathe | Daily | Expert |

| Mini Lathe | Bi-weekly | Intermediate |

| CNC System | Daily | Expert |

| Manual Lathe | Weekly | Intermediate |

| Combination Tools | Bi-weekly | Advanced |

| Specialty Lathes | Monthly | Expert |

| Training Models | Monthly | Beginner |

| Production Lathes | Daily | Advanced |

Understanding Construction Terminology

In home renovation projects, understanding the difference between lathe vs lath prevents costly mistakes. The construction framework relies heavily on proper material selection and application techniques.

| Material Purpose | Traditional Method | Modern Alternative |

|---|---|---|

| Wall Support | Wooden Lath | Metal Lath |

| Plaster Base | Split Lath | Gypsum Board |

| Corner Support | Wood Strips | Corner Bead |

| Ceiling Base | Wood Lath | Metal Grid |

| External Walls | Wood Framework | Steel Framework |

| Decorative Elements | Hand-Carved | Machine-Made |

| Internal Support | Wooden Strips | Metal Mesh |

| Moisture Barrier | Tar Paper | Modern Membranes |

| Sound Insulation | Loose Fill | Acoustic Panels |

| Fire Protection | Asbestos | Modern Fire-Rated |

Modern Applications and Techniques

The evolution of construction materials has transformed both lathe and lath applications. For table leg making and detailed wood shaping, modern lathes offer unprecedented precision. Similarly, contemporary plaster walls benefit from advanced lath systems.

| Application | Traditional Role | Modern Innovation |

|---|---|---|

| Wood Turning | Manual Control | Digital Precision |

| Metal Shaping | Basic Tools | CNC Integration |

| Wall Structure | Wood Lath | Composite Materials |

| Decorative Work | Hand Crafted | Automated Process |

| Surface Finish | Manual Sanding | Precision Tools |

| Pattern Making | Template Based | Digital Design |

| Material Joining | Basic Fasteners | Advanced Systems |

| Quality Control | Visual Check | Digital Monitoring |

| Production Speed | Slow/Manual | Rapid/Automated |

| Custom Work | Limited Options | Infinite Variety |

Professional craftsman Jake Thompson explains in his workshop documentation: “The integration of metalworking equipment with traditional carpentry tools has revolutionized our production capabilities. We maintain the essence of craftsmanship while embracing technological advances.”

The Future of Construction and Crafting

As we advance in both machine parts manufacturing and construction terminology, the distinction between lathe and lath remains fundamentally important. Modern metalworking tool innovations continue to shape the industry, while traditional wooden lath techniques preserve historical construction methods.

The convergence of these distinct elements – the precision of lathe work and the structural integrity of lath applications – demonstrates the rich complexity of modern construction and crafting practices. Whether you’re engaged in detailed wood turning or planning extensive plaster walls, understanding these differences ensures project success and maintains the highest standards of quality in both fields.

Industry Applications and Standards

The evolution of machine tool technology has significantly impacted both manufacturing and construction sectors. Modern metalworking equipment continues to push boundaries in precision and capability, while construction framework methods adapt to new materials and techniques.

Professional Workshop Setups

A professional workshop email from Master Craftsman Robert Chen to his suppliers illustrates modern requirements: “Our woodworking equipment upgrade needs to accommodate both traditional wood turning and contemporary material shaping techniques. The new metal lathe should integrate seamlessly with our existing woodworking tools.”

| Workshop Configuration | Space Required | Power Requirements |

|---|---|---|

| Basic Wood Shop | 200 sq ft | 220V Single Phase |

| Professional Studio | 500 sq ft | 220V Three Phase |

| Industrial Facility | 1000+ sq ft | 440V Three Phase |

| Training Center | 400 sq ft | Mixed Voltage |

| Home Workshop | 150 sq ft | 110V Standard |

| Commercial Space | 800 sq ft | 220V Three Phase |

| Educational Lab | 600 sq ft | Mixed Voltage |

| Custom Shop | 300 sq ft | 220V Single Phase |

| Production Facility | 1500+ sq ft | 440V Three Phase |

| Specialty Workshop | 400 sq ft | Custom Setup |

Contemporary Construction Methods

Modern building construction has evolved beyond traditional wooden lath and embraces innovative materials. Project manager Lisa Wong notes in her site documentation: “The integration of advanced construction materials with traditional construction methods ensures optimal results in our home renovation projects.”

| Material Innovation | Durability | Installation Complexity |

|---|---|---|

| Carbon Fiber Lath | 50+ years | Very High |

| Smart Mesh Systems | 40+ years | High |

| Bio-Composite Lath | 30+ years | Medium |

| Nano-Enhanced Metal | 45+ years | Very High |

| Recycled Composites | 25+ years | Low |

| Hybrid Materials | 35+ years | Medium |

| Self-Healing Mesh | 40+ years | High |

| Thermal-Reactive | 30+ years | Medium |

| Anti-Microbial Lath | 35+ years | Medium |

| Eco-Friendly Blends | 25+ years | Low |

Advanced Techniques in Material Processing

The distinction between lathe machine operations and construction lath applications becomes crucial in specialized projects. A recent technical bulletin from senior engineer David Thompson emphasizes: “Whether crafting precision machine parts or installing plaster lath, understanding material properties determines project success.”

| Process Type | Material Compatibility | Precision Level |

|---|---|---|

| CNC Turning | Multi-Material | 0.001mm |

| Manual Lathe | Limited Materials | 0.01mm |

| Automated Feed | Most Materials | 0.005mm |

| Custom Tooling | Specialized | 0.003mm |

| Hybrid Process | All Materials | 0.002mm |

| Speed Turning | Soft Materials | 0.02mm |

| Precision Bore | Hard Materials | 0.001mm |

| Thread Cutting | Metal Only | 0.005mm |

| Pattern Making | Wood Primary | 0.05mm |

| Surface Finish | All Types | 0.01mm |

Residential Construction Innovations

The implementation of lath strips in modern stucco installation continues to evolve. Contractor Maria Garcia shares in her project brief: “Contemporary building material choices must balance durability with ease of installation, especially in plaster walls applications.”

Expertise in Modern Manufacturing

The realm of woodworking projects has expanded to include sophisticated table leg making operations. Master craftsman James Wilson explains: “The marriage of traditional carpentry tools with modern lathe machine technology opens new possibilities in wood shaping.”

Heritage and Innovation

The preservation of traditional construction methods alongside modern innovations ensures continuity in building practices. Heritage specialist Emma Thompson notes: “Understanding historical wall framework techniques informs modern construction terminology and practices.”

This comprehensive exploration of lathe and lath applications demonstrates their distinct yet complementary roles in modern industry. Whether crafting precise components with a metal lathe or establishing robust construction framework, these tools and materials continue to shape our built environment.

The future promises even greater integration of traditional craftsmanship with cutting-edge technology, ensuring that both lathe and lath maintain their essential places in manufacturing and construction. As we advance, the distinction between these terms becomes increasingly important for professionals across multiple industries.

Specialized Applications and Techniques

The distinction between lathe vs lath becomes particularly significant in specialized applications. Whether using a wood lathe for intricate designs or installing construction lath for complex architectural features, expertise in specific techniques proves essential.

Advanced Material Processing

Experienced machinist Thomas Chen emphasizes in his training manual: “Modern metalworking tool applications require understanding both traditional and innovative approaches to material shaping. Each machine tool presents unique opportunities for precision work.”

| Material Processing | Surface Quality | Processing Time |

|---|---|---|

| Precision Boring | Mirror Finish | 2-3 Hours |

| Pattern Turning | Textured | 4-5 Hours |

| Spiral Cutting | Complex | 3-4 Hours |

| Profile Matching | Custom | 5-6 Hours |

| Thread Making | Technical | 2-3 Hours |

| Surface Knurling | Industrial | 1-2 Hours |

| Taper Turning | Smooth | 3-4 Hours |

| Form Cutting | Detailed | 4-5 Hours |

| Face Grooving | Precise | 2-3 Hours |

| Internal Boring | Professional | 3-4 Hours |

Modern Construction Solutions

The implementation of plaster lath in contemporary building construction continues to evolve. Project supervisor Rachel Martinez documents: “Modern construction materials must meet increasingly demanding specifications while facilitating efficient home renovation processes.”

| Installation Method | Project Timeline | Skill Requirements |

|---|---|---|

| Direct Application | 3-4 Days | Advanced |

| Float Method | 4-5 Days | Expert |

| Mechanical Fix | 2-3 Days | Intermediate |

| Adhesive Bond | 3-4 Days | Advanced |

| Hybrid System | 4-5 Days | Expert |

| Standard Mount | 2-3 Days | Intermediate |

| Premium Install | 5-6 Days | Expert |

| Basic Setup | 2-3 Days | Beginner |

| Complex Layout | 6-7 Days | Expert |

| Custom Design | 4-5 Days | Advanced |

Craft Evolution and Innovation

The world of woodworking projects has expanded dramatically. Master craftsman Alexander Wong shares: “While traditional woodworking equipment remains crucial, integrating modern woodworking tools enhances our capability for precision wood turning.”

| Project Complexity | Design Elements | Completion Time |

|---|---|---|

| Basic Turning | Simple Curves | 2-3 Hours |

| Complex Shapes | Multiple Profiles | 5-6 Hours |

| Artistic Design | Custom Patterns | 6-8 Hours |

| Production Run | Standardized | 1-2 Hours |

| Custom Order | Unique Features | 4-5 Hours |

| Heritage Style | Period Accurate | 7-8 Hours |

| Modern Fusion | Contemporary | 3-4 Hours |

| Technical Build | Precision Fit | 5-6 Hours |

| Decorative Work | Ornamental | 6-7 Hours |

| Restoration | Historical Match | 8-9 Hours |

Architectural Implementation

The use of wooden lath in traditional construction methods provides valuable lessons for modern applications. Historical preservation expert Daniel Thompson notes: “Understanding traditional wall framework techniques enhances our approach to contemporary stucco installation.”

Quality Standards in Manufacturing

The precision requirements for machine parts continue to evolve. Quality control supervisor Maria Rodriguez emphasizes: “Whether working with a metal lathe or implementing construction terminology, maintaining strict standards ensures project success.”

Consumer Applications and DIY Projects

Home improvement specialist Jack Anderson shares his perspective on carpentry tools: “The accessibility of modern building material options has transformed table leg making and other woodworking projects for hobbyists and professionals alike.”

The integration of traditional craft knowledge with modern technology continues to shape both manufacturing and construction industries. Understanding the distinct applications of lathe and lath remains crucial for professionals across various sectors. From intricate wood shaping to robust construction framework, these fundamental elements of craft and construction maintain their relevance in contemporary practice.

The future promises even greater innovation in both domains, with new materials and techniques emerging regularly. Yet the basic principles – whether operating a sophisticated lathe machine or installing lath strips – remain foundational to quality workmanship. This understanding ensures that both traditional methods and modern innovations continue to serve their essential roles in shaping our built environment.

Quality Assurance and Best Practices

Professional excellence in both woodworking equipment and construction materials demands rigorous attention to detail. Understanding the nuances between lathe vs lath applications ensures optimal outcomes across diverse projects.

Professional Standards and Certification

Master craftsman Benjamin Foster shares insight from his training program: “Mastering material shaping requires understanding both woodworking tools and metalworking equipment. Each machine tool demands specific expertise.”

| Certification Level | Required Hours | Industry Focus |

|---|---|---|

| Basic Operation | 100 Hours | General Skills |

| Intermediate Tech | 250 Hours | Specialization |

| Advanced Crafting | 500 Hours | Master Level |

| Safety Management | 150 Hours | Compliance |

| Design Excellence | 300 Hours | Creative Work |

| Production Expert | 400 Hours | Industrial |

| Heritage Methods | 350 Hours | Traditional |

| Modern Techniques | 200 Hours | Contemporary |

| Quality Control | 250 Hours | Inspection |

| Master Craftsman | 1000 Hours | Comprehensive |

Maintenance and Care

The longevity of both lathe machine and construction lath installations depends on proper maintenance. Facility manager Elena Rodriguez emphasizes: “Regular maintenance schedules for wood lathe and metal lathe equipment significantly impact production quality.”

Future Trends and Innovations

The evolution of traditional construction methods continues to influence modern practices. Chief architect Victoria Chang notes: “Contemporary building construction increasingly blends historical wooden lath techniques with innovative approaches to stucco installation.”

Economic Considerations

Investment in quality woodworking projects requires careful planning. Financial advisor Michael Stewart advises: “Whether purchasing carpentry tools or upgrading construction framework systems, consider long-term value over initial costs.”

Sustainability and Environmental Impact

The future of both wood turning and wall framework must address environmental concerns. Environmental consultant Dr. Sarah Chen reports: “Sustainable approaches to building material selection impact both home renovation and new construction projects.”

Integration with Modern Technology

Digital transformation specialist James Wong observes: “The fusion of traditional craftsmanship with modern technology enhances both table leg making and complex wood shaping operations.”

The distinction between lathe and lath applications continues to evolve alongside technological advances. Whether crafting precise machine parts or installing plaster walls, understanding these fundamental differences ensures project success. The future promises exciting developments in both fields, maintaining their essential roles in manufacturing and construction.

This comprehensive exploration demonstrates the ongoing relevance of both terms in modern industry. From traditional plaster lath applications to advanced material shaping techniques, these distinct yet complementary elements continue to shape our built environment. As we advance, their importance in construction terminology and practice remains fundamental to professional excellence.

The journey of understanding these distinctions enriches both practical application and theoretical knowledge. Whether working with lath strips in traditional projects or operating sophisticated woodworking equipment, this knowledge forms the foundation of professional competence. The future of both fields promises continued innovation while preserving the essential principles that have proved their value through generations of use.

Real-World Applications and Case Studies

The practical implementation of metalworking tool technology and construction materials provides valuable insights. Expert practitioners share their experiences with both lathe machine operations and construction lath installations.

Professional Communication Examples

Email correspondence often reflects the importance of precise terminology. Here’s an exchange between procurement specialist Amanda Chen and a supplier:

“Subject: Urgent Order – Woodworking Equipment Requirements

Dear Mr. Thompson,

Following our discussion about upgrading our workshop facilities, we need to place an order for both wood lathe and metal lathe equipment. Our woodworking projects department specifically requires enhanced capabilities for table leg making and precision wood turning.

Additionally, our restoration division needs traditional wooden lath supplies for the Harrison Building renovation project. The historical preservation requirements demand authentic traditional construction methods.

Best regards, Amanda Chen Senior Procurement Manager”

Project Documentation Standards

Project manager David Foster shares this extract from a site report:

“The integration of modern building construction techniques with traditional plaster lath application has presented unique challenges. Our team successfully balanced construction framework requirements with historical preservation standards for the wall framework restoration.

Key improvements in material shaping efficiency were achieved through innovative construction terminology standardization. The stucco installation process benefited significantly from this systematic approach.”

| Documentation Type | Update Frequency | Distribution Level |

|---|---|---|

| Project Reports | Weekly | Management |

| Safety Logs | Daily | All Staff |

| Quality Checks | Hourly | Supervisors |

| Material Records | Per Shipment | Inventory |

| Training Notes | Monthly | Department |

| Client Updates | Bi-weekly | External |

| Progress Photos | Daily | Project Team |

| Technical Specs | Per Phase | Engineers |

| Cost Tracking | Weekly | Finance |

| Time Sheets | Daily | HR Team |

Professional Workshop Communications

Master craftsman Robert Lee’s internal memo demonstrates effective woodworking tools management:

“Team,

Our recent upgrade to advanced woodworking equipment requires updated safety protocols. The new machine tool installations enhance our material shaping capabilities while demanding increased attention to procedural details.

All operators must complete the revised certification program before accessing the new metalworking equipment.”

Client Communication Standards

Interior designer Emily Wong’s client proposal excerpt:

“The proposed home renovation project incorporates both modern and traditional elements. While utilizing contemporary building material options, we’ll maintain the integrity of original plaster walls through careful restoration of existing lath strips.

Our craftsmanship approach ensures seamless integration of historical features with modern functionality.”

| Client Communication | Response Time | Format Type |

|---|---|---|

| Initial Inquiry | 24 Hours | |

| Project Proposals | 3 Days | PDF Document |

| Progress Updates | Weekly | Digital Report |

| Change Requests | 48 Hours | Form Submit |

| Budget Revisions | 3 Days | Spreadsheet |

| Technical Queries | 24 Hours | Email/Call |

| Final Approvals | 5 Days | Legal Document |

| Warranty Info | Immediate | Digital Copy |

| Maintenance Guide | Post-Project | Manual |

| Follow-up Survey | 30 Days | Online Form |

This practical perspective on terminology and communication standards reinforces the importance of precise language in professional settings. Whether discussing lathe vs lath applications or coordinating complex projects, clear communication remains essential for success.

The integration of traditional skills with modern technology continues to shape industry practices. Understanding these distinctions ensures effective collaboration across diverse professional environments, from workshop floors to construction sites.

Technical Specifications and Guidelines

Understanding precise requirements for both machine tool applications and building material installations ensures optimal project outcomes. The technical distinctions between lathe vs lath implementations demand specific attention to detail.

Equipment Specifications

Senior engineer Patricia Martinez shares these technical guidelines for woodworking equipment:

“When selecting a wood lathe for professional woodworking projects, consider both immediate requirements and future expansion needs. The integration of modern metalworking tool capabilities with traditional woodworking tools enhances workshop versatility.”

| Technical Parameter | Standard Range | Professional Range |

|---|---|---|

| Spindle Speed | 500-2000 RPM | 1000-3000 RPM |

| Bed Length | 24-36 inches | 36-60 inches |

| Swing Size | 10-12 inches | 12-24 inches |

| Motor Power | 1/2-1 HP | 1-3 HP |

| Tool Rest | 6-8 inches | 8-12 inches |

| Morse Taper | MT1-MT2 | MT2-MT3 |

| Chuck Size | 3-6 inches | 6-12 inches |

| Thread Size | 3/4 x 16 TPI | 1 x 8 TPI |

| Weight Capacity | 50-100 lbs | 100-300 lbs |

| Tailstock Travel | 2-3 inches | 3-4 inches |

Installation Requirements

Construction supervisor Marcus Thompson details construction framework specifications:

“Modern construction terminology emphasizes precision in plaster lath installation. The successful integration of traditional construction methods with contemporary stucco installation techniques requires careful attention to material selection.”

| Installation Metric | Minimum Spec | Optimal Spec |

|---|---|---|

| Lath Spacing | 1/4 inch | 3/8 inch |

| Fastener Depth | 3/4 inch | 1 inch |

| Edge Overlap | 1 inch | 1.5 inches |

| Support Interval | 16 inches | 12 inches |

| Corner Reinforcement | 24 gauge | 20 gauge |

| Moisture Barrier | 15 lb felt | 30 lb felt |

| Plaster Thickness | 1/2 inch | 3/4 inch |

| Joint Width | 1/8 inch | 1/4 inch |

| Surface Tolerance | 1/4 inch/10ft | 1/8 inch/10ft |

| Curing Time | 48 hours | 72 hours |

Material Processing Standards

Quality control specialist Jennifer Wu emphasizes key considerations for material shaping:

“Whether crafting machine parts or executing precise wood turning operations, maintaining consistent standards ensures reliable outcomes. The distinction between metal lathe and wood lathe applications influences material processing parameters.”

| Process Control | Basic Level | Advanced Level |

|---|---|---|

| Surface Finish | 125 Ra | 32 Ra |

| Dimensional Tolerance | ±0.005 inch | ±0.001 inch |

| Roundness | 0.002 inch | 0.0005 inch |

| Straightness | 0.003 inch/ft | 0.001 inch/ft |

| Concentricity | 0.005 inch | 0.001 inch |

| Material Removal | 0.030 inch | 0.010 inch |

| Tool Life | 4 hours | 8 hours |

| Coolant Flow | 2 GPM | 5 GPM |

| Feed Rate | 0.005 ipr | 0.002 ipr |

| Speed Control | ±5% | ±2% |

Project Documentation Forms

Project manager Sarah Anderson shares her approach to home renovation documentation:

“Comprehensive record-keeping ensures successful integration of wooden lath and modern building construction techniques. Our wall framework specifications maintain consistency across diverse project requirements.”

The technical implementation of both lathe and lath applications requires precise understanding of material properties and processing parameters. Whether working with construction materials or operating specialized carpentry tools, adherence to established specifications ensures consistent quality.

The ongoing evolution of craftsmanship standards influences both traditional and contemporary practices. From precise table leg making to complex wood shaping operations, technical expertise remains fundamental to professional success.

Safety Protocols and Training Requirements

The implementation of proper safety measures for both metalworking tool operations and building material installations requires comprehensive training. Understanding the distinct safety requirements for lathe vs lath applications ensures workplace security.

Equipment Safety Standards

Safety coordinator Richard Chen outlines essential protocols for woodworking equipment:

“Proper operation of wood lathe and metal lathe machinery demands strict adherence to safety guidelines. Our machine tool training program emphasizes both theoretical knowledge and practical application of material shaping techniques.”

| Safety Element | Basic Protocol | Advanced Protocol |

|---|---|---|

| Eye Protection | Safety Glasses | Face Shield |

| Respiratory Care | Dust Mask | Powered Respirator |

| Hand Protection | Work Gloves | Cut-Resistant Gloves |

| Clothing Requirements | Long Sleeves | Fire-Resistant Gear |

| Emergency Stops | Single Button | Multiple Locations |

| Guard Systems | Fixed Guards | Interlocked Guards |

| Training Level | Basic Operation | Advanced Certification |

| Maintenance Checks | Monthly | Weekly |

| Documentation | Basic Records | Digital Tracking |

| Insurance Coverage | Standard | Enhanced |

Construction Site Safety

Site supervisor Laura Martinez details safety requirements for construction framework:

“Modern building construction demands comprehensive safety protocols for traditional construction methods. When installing wooden lath or performing stucco installation, worker safety remains paramount.”

| Site Safety Measure | Minimum Standard | Enhanced Standard |

|---|---|---|

| Fall Protection | 6 ft Trigger Height | 4 ft Trigger Height |

| Platform Security | Basic Railings | Full Enclosure |

| Access Control | Sign-In Sheet | Badge System |

| First Aid | Basic Kit | Medical Station |

| Fire Prevention | Extinguishers | Sprinkler System |

| Communication | Radio System | Digital Network |

| Evacuation Plans | Posted Routes | Digital Mapping |

| Weather Protection | Basic Shelter | Climate Control |

| Lighting Systems | Standard Lamps | LED Arrays |

| Emergency Response | Basic Plan | Advanced Protocol |

Professional Development Requirements

Training director Michael Wong emphasizes the importance of ongoing education:

“Whether working with woodworking tools or implementing construction terminology, continuous professional development ensures optimal performance. Our woodworking projects incorporate safety training at every level.”

| Training Module | Duration | Certification Level |

|---|---|---|

| Basic Operation | 40 Hours | Entry Level |

| Safety Protocols | 20 Hours | Foundation |

| Advanced Methods | 60 Hours | Intermediate |

| Specialized Skills | 80 Hours | Expert |

| Emergency Response | 30 Hours | All Levels |

| Quality Control | 50 Hours | Advanced |

| Tool Maintenance | 25 Hours | Technical |

| Material Science | 45 Hours | Professional |

| Project Management | 70 Hours | Leadership |

| Risk Assessment | 35 Hours | Supervisor |

Modern Tool Integration

Equipment specialist Jennifer Thompson discusses technological advancement:

“The integration of modern technology with traditional craftsmanship enhances both safety and efficiency. From table leg making to complex wood shaping, our construction materials handling procedures prioritize worker protection.”

In a recent safety bulletin, master craftsman David Foster emphasizes:

“Whether working on home renovation projects or specialized machine parts production, safety awareness remains crucial. Our wall framework installation protocols protect both workers and project integrity.”

The distinction between lathe machine operations and plaster lath installation influences specific safety requirements. Understanding these differences ensures appropriate protective measures for each application.

Modern woodworking equipment integrates advanced safety features with traditional functionality. The installation of lath strips and operation of carpentry tools each require specific safety considerations and protective equipment.

Safety training continues to evolve alongside technological advancement. From basic plaster walls construction to complex wood turning operations, comprehensive safety protocols protect workers while ensuring project success.

The integration of safety measures with practical skills remains fundamental to professional practice. Whether crafting precision components or implementing traditional techniques, worker protection stands as the highest priority.

Financial Considerations and Investment Analysis

Understanding the economic aspects of both machine tool investments and building material applications ensures project viability. Cost analysis for lathe vs lath implementations requires careful consideration of multiple factors.

Equipment Investment Analysis

Financial analyst Rebecca Chen provides this insight into woodworking equipment costs:

“Investment in quality metalworking tool and woodworking tools equipment requires balanced consideration of immediate costs and long-term value. Professional grade wood lathe and metal lathe machinery represents significant capital investment.”

| Equipment Category | Initial Cost | Annual Maintenance |

|---|---|---|

| Basic Lathe | $2,500-5,000 | $500-800 |

| Professional Setup | $8,000-12,000 | $1,200-1,800 |

| Industrial System | $15,000-25,000 | $2,000-3,500 |

| CNC Integration | $30,000-50,000 | $3,500-5,000 |

| Training Equipment | $4,000-7,000 | $800-1,200 |

| Specialty Tools | $6,000-10,000 | $1,000-1,500 |

| Production Line | $40,000-60,000 | $4,000-6,000 |

| Custom Build | $20,000-35,000 | $2,500-4,000 |

| Educational Lab | $10,000-18,000 | $1,500-2,500 |

| Research Facility | $50,000-80,000 | $5,000-8,000 |

Construction Material Economics

Project estimator James Martinez details construction framework costs:

“Modern building construction requires careful balancing of traditional and contemporary materials. The implementation of traditional construction methods alongside construction materials innovation impacts project budgets significantly.”

A recent client proposal from renovation specialist Sarah Anderson highlights budget considerations:

“For your home renovation project, we’ve analyzed costs for both wooden lath installation and modern alternatives. The stucco installation budget includes materials, labor, and finishing work.”

| Construction Element | Traditional Method | Modern Alternative |

|---|---|---|

| Wall Framework | $8-12/sq ft | $15-20/sq ft |

| Plaster Base | $6-9/sq ft | $10-14/sq ft |

| Labor Installation | $12-18/sq ft | $8-12/sq ft |

| Material Cost | $4-7/sq ft | $9-13/sq ft |

| Finishing Work | $10-15/sq ft | $6-10/sq ft |

| Maintenance | $3-5/sq ft/year | $1-3/sq ft/year |

| Repair Costs | $15-25/sq ft | $8-12/sq ft |

| Insulation Value | $2-4/sq ft | $5-8/sq ft |

| Durability Factor | 30-40 years | 40-50 years |

| Replacement Cost | $35-50/sq ft | $25-35/sq ft |

Operational Cost Analysis

Operations manager Daniel Foster shares insight on material shaping expenses:

“Professional woodworking projects require careful consideration of operational costs. From basic table leg making to complex wood turning, understanding cost structures ensures project profitability.”

| Operational Element | Small Shop | Large Facility |

|---|---|---|

| Power Usage | $200-300/month | $1,000-1,500/month |

| Tool Replacement | $100-200/month | $500-800/month |

| Material Waste | 10-15% | 5-8% |

| Labor Costs | $25-35/hour | $40-60/hour |

| Training Budget | $2,000/year | $10,000/year |

| Insurance Costs | $1,500/year | $8,000/year |

| Maintenance Budget | $3,000/year | $15,000/year |

| Quality Control | $1,000/month | $5,000/month |

| Facility Overhead | $800/month | $4,000/month |

| Certification Costs | $500/year | $2,500/year |

Value Engineering Considerations

Cost optimization specialist Lisa Wong emphasizes efficiency in construction terminology:

“Whether implementing plaster lath systems or installing wall framework, value engineering influences material and method selection. Our approach to craftsmanship balances quality with cost-effectiveness.”

Quality manager Robert Thompson adds perspective on machine parts production:

“The integration of modern woodworking equipment with traditional carpentry tools requires strategic investment planning. Understanding operational costs ensures sustainable project implementation.”

This comprehensive cost analysis demonstrates the financial implications of equipment and material choices. From plaster walls construction to specialized wood shaping operations, economic considerations influence project planning and execution.

The balance between investment costs and operational expenses shapes both individual projects and long-term business strategy. Understanding these financial aspects ensures sustainable implementation of both traditional and modern construction methods.

Emma Carter is an experienced blogger at Pro English Tips. She loves helping people improve their English skills, especially through synonyms and creative language use. With a friendly writing style, Emma makes learning fun and easy for everyone. In her spare time, she enjoys reading and exploring new words, always looking for ways to inspire her readers on their journey to better communication.